Srikar Industries Pvt Ltd, from Fusion Group, has established a plant for manufacturing of wall panels under the brand name of FUSION. The idea of Fusion wall panels stems from group's commitment to create greener buildings, for a greener planet. Our wall panels are environment friendly and a ready-made solution for residential and industrial projects. Our unique ready-to-install wall panels are poised to revolutionise building construction on cost and time saving.

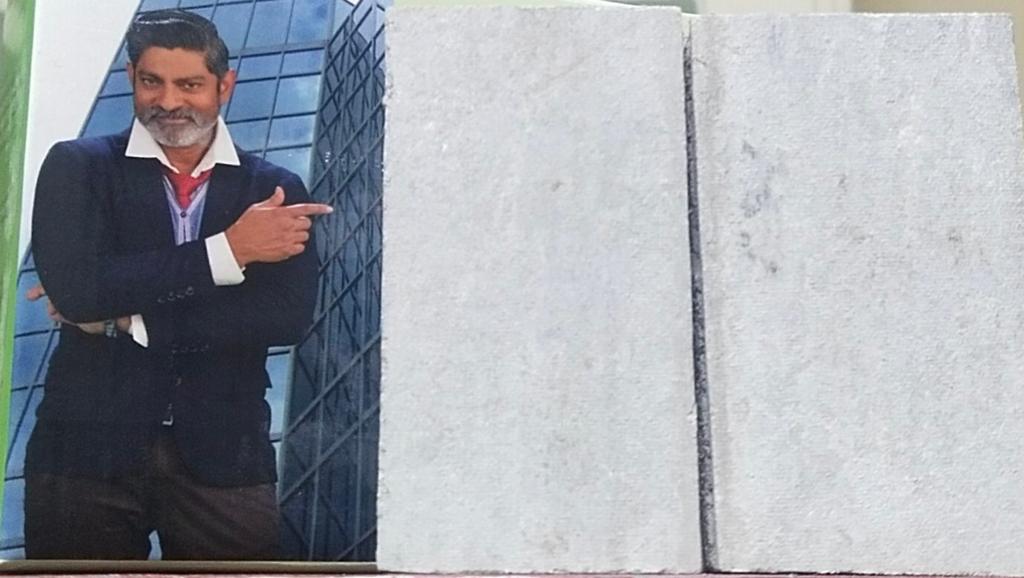

Fusion wall Panels are made up of light weight aerated concrete core sandwiched between two fibre reinforced cement sheets. Our manufacturing facility is ISO 9001:2015 compiled.

We are manufacturing 50 mm and 75 mm Thickness walls.

50 mm - Thickness

10 feet height x 2 feet width x 2 inches thickness (3000 mm x 600 mm x 50 mm)

9 feet height x 2 feet width x 2 inches thickness(2700 mm x 600 mm x 50 mm)

8 feet height x 2 feet width x 2 inches thickness (2400 mm x 600 mm x 50 mm)

75 mm -Thickness

10 feet height x 2 feet width x 3 inches thickness (3000 mm x 600 mm x 75 mm)

9 feet height x 2 feet width x 3 inches thickness (2700 mm x 600 mm x 75 mm)

8 feet height x 2 feet width x 3 inches thickness (2400 mm x 600 mm x 75 mm)

If you have any construction and renovation work need, please

call.

+91 - 7032 992 034 or Contact Us

Copyright © Fusion Block 2020. All rights reserved.